On site cement-lining

ON SITE CEMENT LINING

In-Situ lining can be done anywhere in the world. Equipment and crew are sent to the site for lining of sections of pre-installed underground or above ground pipework. The lining will meet the same requirements as lining applied in the shop.

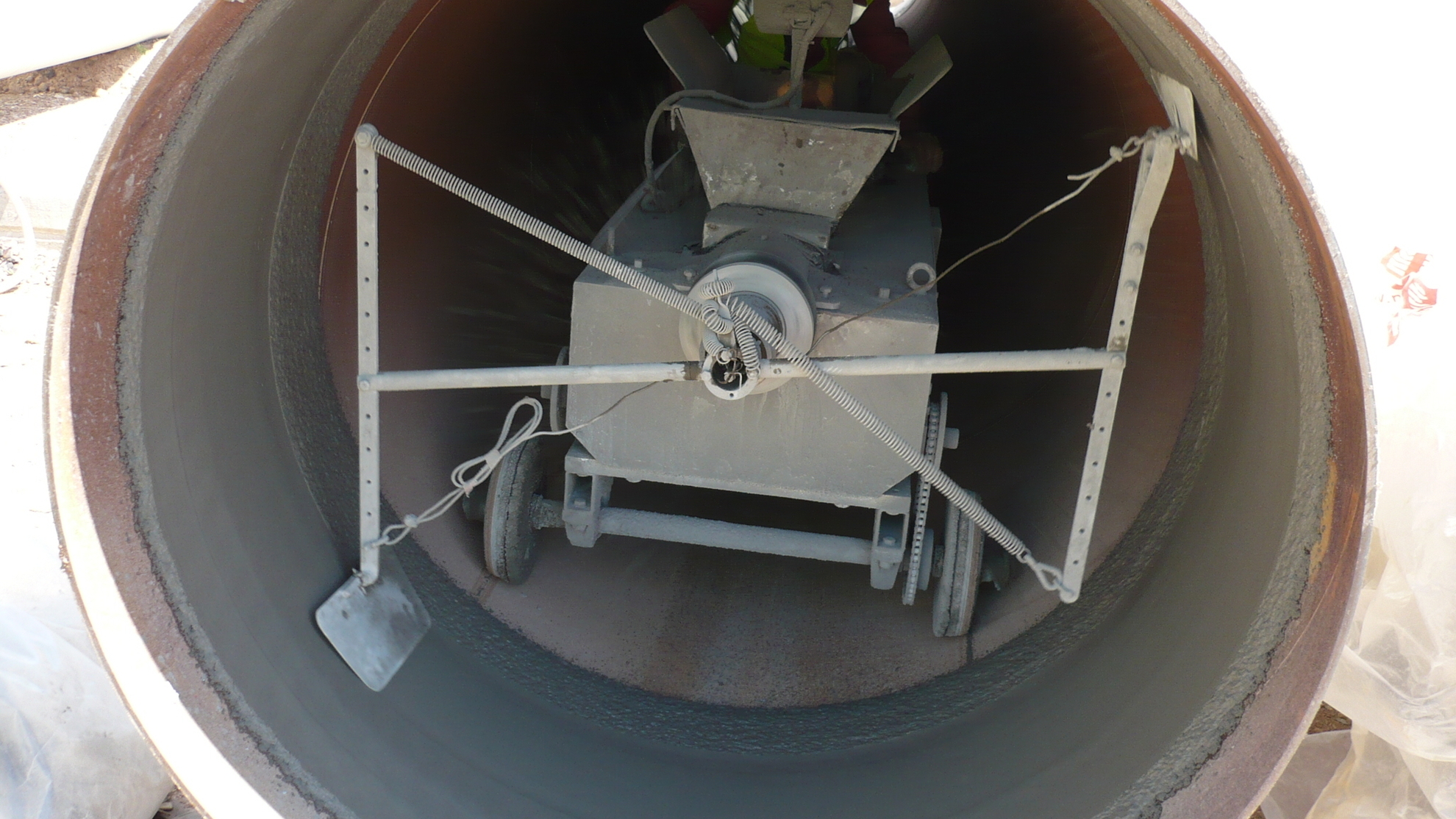

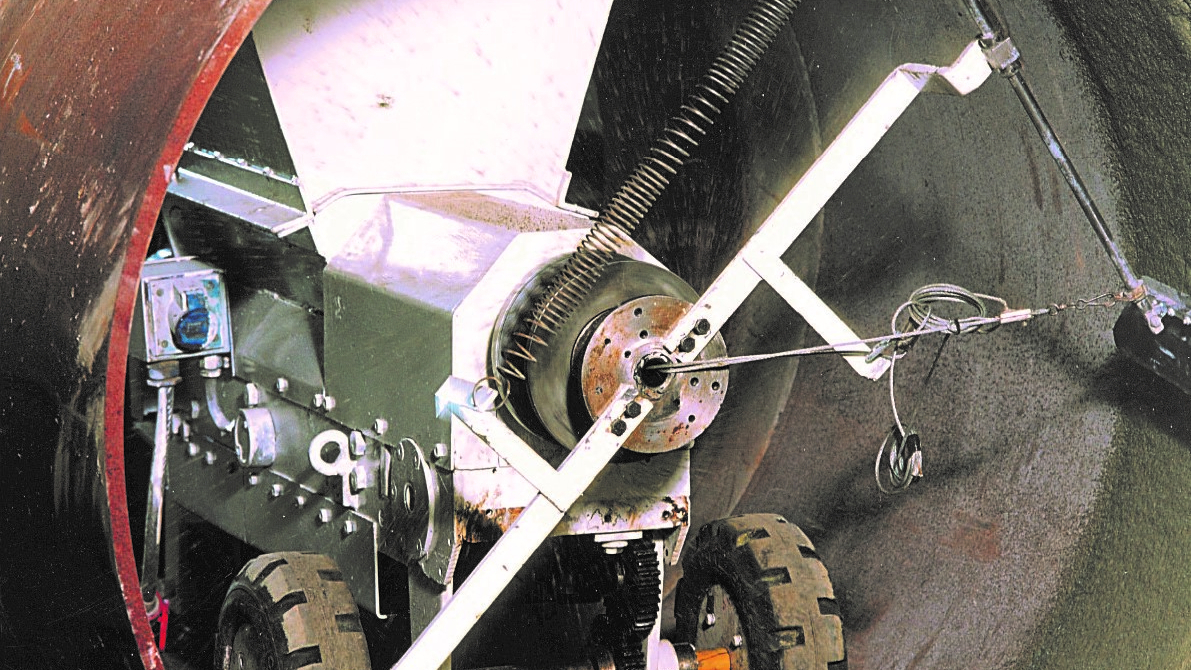

Pipes over 24” and up 120” in diameter are lined by the so-called man-entry method. The machine operator travels along the pipe with the lining machine. The cementmortar is sprayed against the pipewall and smoothened by a rotating trowel blades or static dragtrowel.

In case of smaller sizes only the lining machine is sent into the pipes. Limitations in the pipe length that can be lined In-Situ depend on the size and position of the pipeline.

To overcome the necessity of shipping the pipes to our factory in Holland.

The pipes can be shipped directly to the site or any location in country.

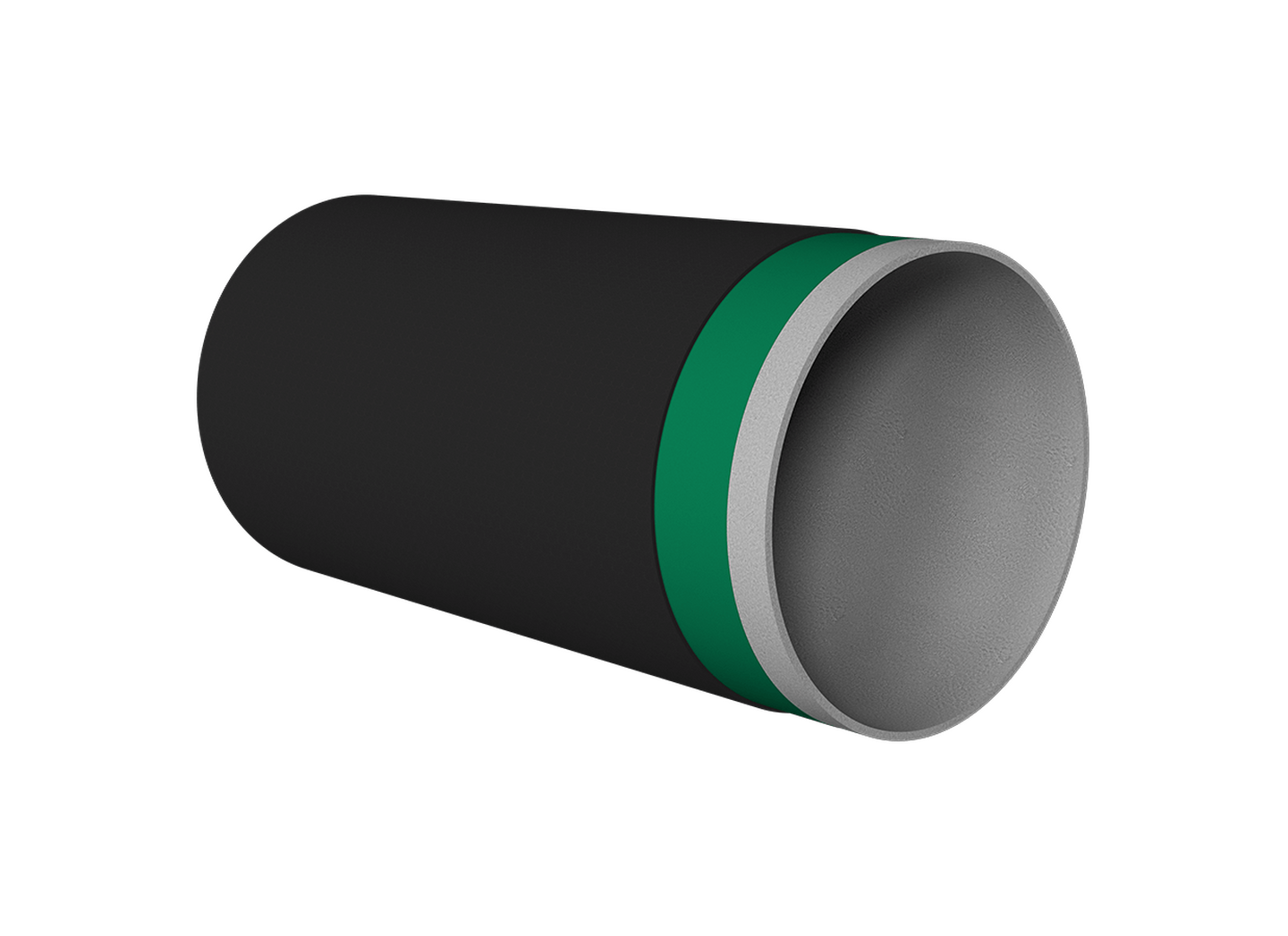

There they can be cement lined by our mobile cement lining machine, which is developed similar to our factory set-up. This set-up can line pipes from 4”upto 48” where the pipe after application of cementmortar will be centrifuged on the same machine to produce a dense lining and to obtain a smooth surface of the lining. The length is limited to 18 m per pipe. To facilitate our equipment and crew the required quantity of pipes should be sufficient to cover the cost of mobilisation and set-up.

Please contact our sales department for more info.